2017/06/01

Part 9: Introduction- Get The Essential Facts About Actuators

Noticias/Artículos

What is an Actuator and How Does It Work?

An actuator is a device that plays a crucial role in modern machinery, converting energy into motion to perform a specific task. It acts as the driving force behind mechanical systems, enabling movement, control, and precision in a wide range of applications. Actuators are indispensable components in applications ranging from industrial automation and robotics to home and healthcare systems, enhancing functionality and efficiency.

At its core, an actuator works by receiving energy—whether it be electrical, hydraulic, or pneumatic—and transforming it into mechanical motion. This motion can be linear (moving in a straight line) or rotary (spinning or turning). For example, in an electric actuator, electrical energy powers a motor, which drives a screw or rod to create linear movement. Hydraulic actuators rely on pressurized fluid, while pneumatic actuators use compressed air to generate force. Each type of actuator is designed to meet specific operational requirements, making it versatile across different industries.

The versatility of actuators extends to their applications, ranging from heavy-duty industrial machinery like cranes and conveyor belts to everyday devices such as adjustable desks and automated window openers. By integrating actuators into systems, manufacturers can achieve higher precision, automation, and reliability.

Understanding how actuators work, and their diverse functionalities is key to selecting the right type for your needs. Whether you need precision, power, or adaptability, actuators provide the foundational movement that brings machines to life, making them essential in today’s technology-driven world. This article delves into the various types of actuators, their uses, and tips for choosing the best solution for your specific applications.

Types of Actuators

Actuators are available in various forms, each designed for specific functionalities. Understanding their unique features and applications is crucial for system integration.

Here are the main types:

-

Electric Actuators

-

How they work:

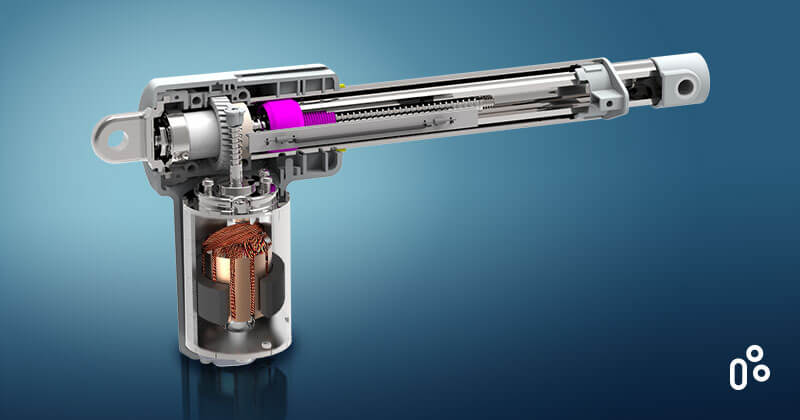

Electric actuators operate by converting electrical energy into mechanical motion, specifically linear or rotary motion. The core component is an electric motor that drives a threaded lead screw. As the motor rotates, the screw moves a nut along its length, producing linear motion. This push-pull effect is what enables the actuator to lift, pull, or push loads. Advanced designs allow precise control of the motor’s speed and direction, enabling smooth and accurate adjustments. Additionally, electric actuators often include sensors or encoders that provide feedback on the actuator’s position, ensuring precision in automation systems. These features make electric actuators a preferred choice for applications requiring high accuracy and repeatability, such as robotics, automotive systems, and medical devices.

-

Strengths:

- Precision and Control: Electric actuators provide excellent precision and control over movement, allowing for exact positioning.

- Energy Efficiency: They typically consume less power compared to other types of actuators, especially in static hold applications.

- Low Maintenance: Electric actuators require minimal maintenance as they have fewer moving parts and do not involve fluids.

-

Hydraulic Actuators

-

How they work:

Hydraulic actuators rely on the principles of fluid dynamics to generate force and motion. A pump delivers pressurized hydraulic fluid (usually oil) through a network of valves and hoses to a cylinder. Inside the cylinder, the fluid pushes against a piston, causing it to move linearly. Valves regulate the fluid’s flow and pressure to control motion. Because hydraulic fluid is incompressible, hydraulic actuators can generate tremendous force with minimal energy loss. This makes them ideal for heavy-duty applications. For example, in construction equipment like excavators, hydraulic actuators enable precise control over large loads, even in challenging environmental conditions. Despite their power, hydraulic systems require regular maintenance to prevent leaks and maintain efficiency.

-

Strengths:

- High Force Capability: Hydraulic actuators can generate significantly higher forces than other types and are suitable for lifting or moving heavy loads.

- Sturdy and Reliable: Well-suited for harsh environments due to their robust construction.

-

Pneumatic Actuators

-

How they work:

Pneumatic actuators use compressed air to produce motion. A compressor generates pressurized air, which is then delivered to a cylinder housing a piston. The air pressure drives the piston along the cylinder’s axis, creating linear force. Once the piston completes its stroke, it returns to its starting position either through spring-back force or by introducing air to the opposite side of the piston. The simplicity of pneumatic systems is one of their greatest advantages. Pneumatic systems are cleaner and less prone to leaks compared to hydraulic actuators, which rely on liquid. They are also highly responsive, providing quick and repetitive motion, making them ideal for manufacturing and assembly lines. However, their reliance on air pressure limits their ability to generate high force compared to hydraulic systems.

-

Strengths:

- Speed: Pneumatic actuators operate very quickly compared to other types, making them ideal for applications requiring rapid movements.

- Simplicity and Cost-effectiveness: These actuators are relatively simple in design and are less expensive to manufacture and maintain.

Read more about Advantages And Drawbacks Of Three Types Of Actuator Systems: Pneumatic, Hydraulic, And Electric.

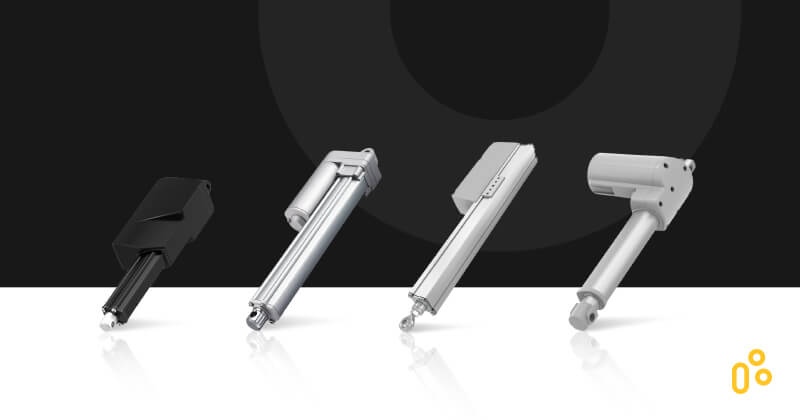

Examples of Electric Actuators

Electric actuators are favored for their precise control and energy efficiency. Common applications include adjustable home furniture, ergonomic office desks, and sophisticated medical equipment. In industrial settings, they facilitate complex automation processes, enhancing productivity and safety with their reliable performance.

Examples of Hydraulic Actuators

Hydraulic actuators are essential in applications requiring significant force, such as in construction machinery and heavy-load systems. They provide the necessary power to operate bulldozers, excavators, and other heavy machinery, which are critical in construction and large-scale manufacturing.

Examples of Pneumatic Actuators

Pneumatic actuators are commonly used where quick, repetitive movements are needed. They are often found in assembly lines, robotics, and pharmaceutical manufacturing, where their simplicity and speed are vital for operational success.

How to Select the Right Actuator?

Selecting the right actuator is a critical decision that depends on a comprehensive understanding of the application's unique demands and operational conditions. To ensure the optimal choice, several key factors must be meticulously evaluated:

1. Define Your Application Goals

-

Load Requirements:

Determine the maximum load the actuator must move. This factor is crucial as it affects the actuator's efficiency and lifespan. Ensure the chosen actuator can handle the load without overstraining its capacity.

-

Speed:

Consider how fast the actuator needs to move to meet your application requirements. Speed affects an actuator's control and precision, especially in time-sensitive applications.

-

Duty Cycle:

Consider the duty cycle, which is the ratio of active time to rest time. Ensure the actuator can handle the frequency of operation required by your application without overheating or wearing out prematurely.

-

Accuracy and Precision:

Evaluate the precision level required in the actuator’s movements. High precision is essential in applications like robotics and aerospace, where even minor deviations can be critical.

2. Analyze Operating Environment

-

Environment:

Assess the environmental conditions the actuator will be exposed to, such as temperature, moisture, dust, and potential corrosive elements. This assessment will help determine the need for additional features like waterproofing or corrosion-resistant materials.

-

Space and Mounting Options:

Consider installation dimensions and ensure the actuator fits within your system’s layout. Compact designs, like inline electric actuators, are ideal for space-constrained setups.

3. Match the Actuator Type to Your System’s Dynamics

-

Hydraulic Actuators:

Unparalleled for delivering high forces in heavy machinery and industrial applications.

-

Electric Actuators:

Known for precision, energy efficiency, and seamless integration with smart controls.

-

Pneumatic Actuators:

Cost-effective solutions for applications requiring fast, repetitive motion, particularly in clean environments.

4. Consider Long-Term Cost and Efficiency

-

Lifecycle Costs:

Compare upfront costs with maintenance, energy consumption, and replacement intervals.

-

Downtime Risks:

Electric actuators typically require less maintenance and are easier to troubleshoot compared to hydraulic and pneumatic counterparts, reducing potential downtime.

Enhancing System Efficiency with the Right Actuator

Understanding the various types of actuators and their specific applications is crucial for designing and implementing efficient systems. Integrating the appropriate actuator can significantly enhance the capability and performance of any machine.

As a leading provider of electric actuator systems, TiMOTION understands the critical need for products that enhance user experience and operational efficiency. We offer customizable electric linear actuator solutions that cater to a wide range of industrial needs, providing total solutions that drive technological and operational advancements.

Contact us today to discuss your requirements and explore how our innovative electric actuator solutions can enhance your workstations.

Frequently Ask Questions (FAQ)

Q1: What is the purpose of an actuator?

A: Actuators are devices designed to convert electrical, hydraulic, or pneumatic energy into mechanical motion. They serve to control a mechanism or system by moving or controlling a mechanism or system, enabling automated or remote-control operations.

Q2: How do I decide between electric, hydraulic, and pneumatic actuators?

A: Choosing the right actuator depends on your application's requirements. If you need high precision and energy efficiency, electric actuators are ideal. For heavy-duty tasks requiring immense force, hydraulic actuators are better suited. Pneumatic actuators are best for applications needing quick, repetitive movements and where compressed air systems are readily available.

Q3: Can actuators be customized to fit specific applications?

A: Yes, actuators can be highly customized to meet specific needs. For instance, electric actuators can be tailored with adjustable speeds, stroke lengths, and control interfaces. Hydraulic actuators can be designed to handle specific pressure levels, while pneumatic actuators can be adjusted for different air pressures and operating speeds.

Q4: What maintenance is required to keep actuators functioning optimally?

A: Maintenance varies by type. Electric actuators typically require minimal upkeep, focusing on regular inspections for wear and tear. Hydraulic actuators need periodic fluid checks and replacements to prevent leaks and maintain performance. Pneumatic actuators require monitoring of air supply systems to ensure cleanliness and adequate pressure levels.