2022/11/15

How To Choose An Electric Linear Actuator?

Novità e Stampa

There are many types of electric linear actuators to choose from. Discover 5 tips for selecting the right electric linear actuator for your equipment. Speed, load, duty cycle, available installation space, or environment are all criteria to consider when choosing your actuator.

How do you choose an electric linear actuator?

Selecting the correct electric linear actuator is crucial for the success of any electrical equipment development project. Actuators suit a wide range of applications, but each project has its unique requirements. To identify the most suitable electric linear actuator, consider several critical factors: the speed of operation, load capacity, duty cycle, spatial constraints, and the operating environment.

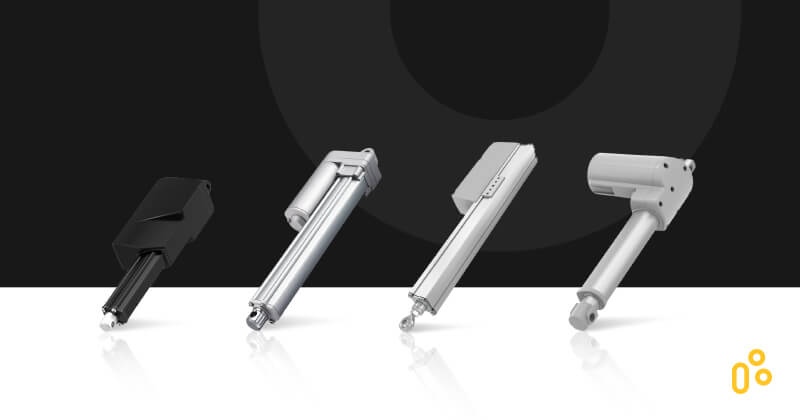

Parallel actuator, L-shaped actuator, in-line actuator, gear motor, or lifting column, which electric actuator will fit your needs? Discover 5 tips for selecting the right electric linear actuator.

5 tips for choosing the right electric linear actuator

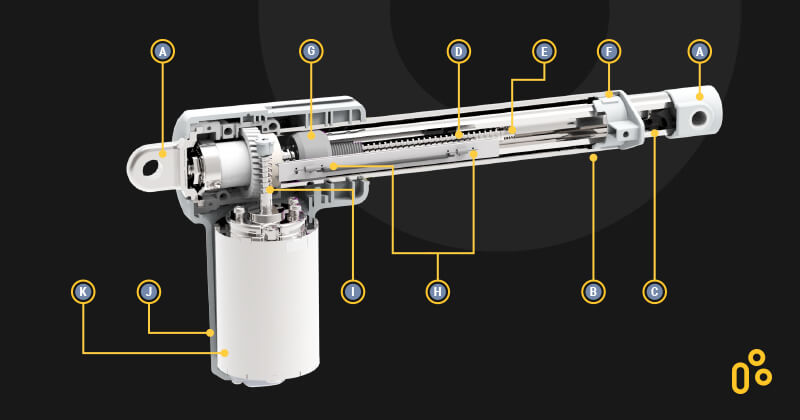

1. Load to be pushed

The load to be pushed is the first criterion to be studied when you choose an actuator. It will define the nature of the components that constitute it and the safety functions to be considered. It is also essential to determine the direction the actuator will have to operate - pull, push, up, down - and over what distance.

2. Required speed of movement

The desired speed of movement is a fundamental criterion in the choice of the actuator. Not all mechanisms or materials are compatible with high speeds. Fast speeds with a high load can cause premature wear of the actuator and impact its life span. Each device has a speed and a load that must not be exceeded to avoid material damage. This speed depends on the screw pitch and the motor characteristics, among other things.

3. Duty cycle

The duty cycle defines the ratio of the operating time to the idle time of a device and varies considerably from application to application. The duty cycle is a critical factor in selecting the actuator, its materials, and its mechanisms. It allows the equipment to have an optimal life span and slows the wear of mechanical parts or possible overheating.

For example, electric linear actuators with parallel motors and spur gears will support a higher duty cycle and may have a higher number of cycles.

4. Available installation space

Choosing an actuator is also based on the installation space available inside the equipment.

Integrating a large electric linear actuator into smaller equipment will be challenging. Therefore, it is essential to know if the device will need to operate in a small space and if there are any space restrictions for optimal integration into the application.

The size of an actuator depends, in part, on its mounting configuration (in-line, L-shaped, or parallel motor mounting). For example, in-line electric actuators are more compact due to the alignment of the motor with the screw and are, therefore, ideal for small installation spaces.

5. Environment

The environment in which the equipment will operate is a determining parameter in choosing the right electric linear actuator. Does the equipment operate indoors or outdoors? Is it subject to dust, solid contaminants, or moisture? Does it have to withstand intensive cleaning with detergents or high-pressure cleaning? The components used and additional IP ratings will differ depending on the environmental requirements.

Does it require a quiet operation? L-shaped electric linear actuators, for example, with their plastic gears and worm wheels, provide a quieter motion, ideal for medical or household equipment.

Therefore, choosing the right electric linear actuator depends on many factors. It is important to select an actuator that can meet the requirements of the application. Every application has a list of unavoidable conditions.

At TiMOTION, technical experts will work with you throughout your project to provide the best solution for your application. Together, you will evaluate the parameters of your application to build a customized device, taking into account your budget.

To go further, discover 10 reasons to adopt electric linear actuators!

TiMOTION is committed to partnering with its customers to provide quality solutions tailored to their specific needs. Contact a local sales representative for more advice!