2024/08/30

Part 5: Dustproof And Waterproof Linear Actuator's IP Rating

News and Articles

Welcome to the part five of our comprehensive guide on electric linear actuators. A critical yet frequently overlooked consideration when purchasing and using electric actuator systems is the importance of IP (Ingress Protection) ratings. These protection ratings are essential for the longevity and reliability of devices, particularly when electric actuators are used in both indoor and outdoor areas.

In this guide, you will gain detailed insight into IP protection types and learn more about their significance for the efficiency and safety of electric actuators.

What are IP Protection Types?

IP protection types represent an internationally recognized classification system that defines the degree of protection electrical devices have against the penetration of solid objects and water. These protection standards are extremely important for electric actuators used in environments with dust, dirt, or moisture. An IP rating consists of two numbers: the first number indicates the level of protection against the entry of solid foreign objects, and the second number describes the level of protection against the entry of liquids.

| IP | 6 | 8 |

|

Ingress Protection |

First Digit: Solids Protection |

Second Digit: Liquids Protection |

Why are IP Protection Types Important?

Choosing the appropriate IP protection type ensures that electric actuators function effectively and safely even under demanding environmental conditions. This extends the lifespan of the devices, reduces maintenance costs, and minimizes the risk of premature failures, resulting in significant cost savings for businesses.

TiMOTION subjects all its finished products to rigorous testing before market launch, exceeding real-world operating conditions to ensure the quality and durability of its products.

What Does the IP Code Mean?

The IP code (International Protection Code) classifies and rates the degree of protection of devices against the penetration of foreign objects such as dust and water. Each of the two digits in the IP code has a specific meaning: the first digit indicates protection against solid objects, while the second digit describes protection against liquids.

- IP Protection Digit 1: This digit ranges from 0 (no protection) to 6 (complete protection against dust). A higher number indicates better protection against the penetration of solid particles such as sand or dust.

- IP Protection Digit 2: This digit ranges from 0 (no protection) to 8 (protection against continuous submersion in water) and even up to 9K (protection against high-pressure cleaning). A higher number means enhanced protection against various forms of moisture or water, from light splashes to complete submersion.

|

Rating |

IP- First Digit Solids Protection |

IP- Second Digit Liquids Protection |

|

0 |

No protection |

|

|

1 |

Solid contaminants > 50 mm |

Vertical water drops |

|

2 |

Solid contaminants > 12.5 mm |

Water drops up to 15° from the vertical |

|

3 |

Solid contaminants > 2,5 mm |

"Raining" water up to 60° from vertical |

|

4 |

Solid contaminants > 1 mm |

Water splashes from all directions |

|

5 |

Dust and microscopic contaminants |

Water jets from all directions |

|

6 |

All solid contaminants |

Strong water jets from all directions |

|

7 |

- |

Temporary immersion up to 1 m, max. 30 min. |

|

8 |

- |

Prolonged immersion |

|

69K |

- |

High-pressure and high-temperature cleaning from all directions |

Common IP Protection Types and Applications

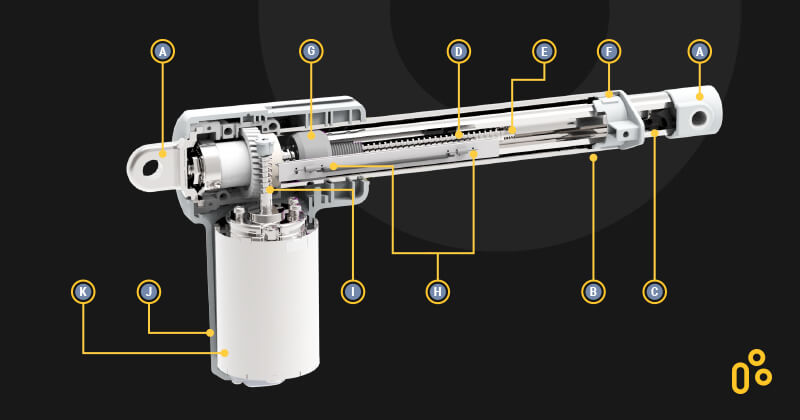

Electric linear actuators can be customized with different IP protection types. The most common ones are: IP42, IP54, IP66, IP67/IP68, and IP69K.

-

IP42

The IP42 rating generally applies to devices used indoors where dust and water pose no significant threat. It is commonly found in devices such as television lifts, sofas, armchairs, or adjustable beds, making it the ideal IP for comfort devices. Examples of electric cylinders and columns with this IP include TVL3, TA5P, TA6, and TA14.

-

IP54

The IP54 rating offers a more universal protection level that allows the operation of actuators in more exposed environments such as hospitals, dental offices, or warehouses. This rating is available as an option for electric cylinders like TA4 and TA23.

-

IP66

The IP66 rating is one of our highest protection levels against solid and liquid contaminants. It is completely protected against the ingress of dust and high-pressure water jets, meaning it can be used in particularly harsh external environments such as construction sites or agricultural operations. The IP66 rating might also be interesting for medical devices that require intensive cleaning with detergents to meet strict hygiene standards (medical beds, patient lifts). IP66 is available as an option for the following electric linear actuators: TA16, TA23, and TA31.

-

IP67 / IP68

The inline electric actuators JP3 and JP4 can optionally be equipped with IP67 or IP68 protection. These are the highest protection levels against liquids, meaning the device is completely sealed. Thanks to the IP67 rating, the device can be submerged in liquids up to one meter deep for 30 minutes. The IP68 rating allows the device to be submerged in a liquid at a depth of more than one meter for one hour. This level of protection is particularly valued in industrial applications such as locks, valves, and other applications with direct water contact. Please note that only IP67 and IP68 allow submersion in water.

-

IP69K

For certain applications, we also offer the IP69K protection type. The IP69K rating is considered the highest level in the industrial market and allows devices to withstand cleaning with high pressure and high temperatures. Please note that a device with the IP69K rating cannot be submerged in water.

Electric linear actuators with IP69K are particularly suitable for use in agricultural environments where there is a high level of dust, dirt, and chemicals. This option is frequently used in our electric industrial cylinders MA1, MA2, MA5, JP3, and JP4.

To learn more about the protection index, click here!

How to Choose the Right IP Protection Rating?

When selecting the right IP protection rating for electric actuators, several important factors must be considered, which can vary depending on the environment in which they are used. Here are some key factors to consider when choosing the right IP rating:

-

Analysis of Environmental Conditions:

- Check whether the electric actuator will be used in environments that are dusty, moist, or potentially contaminated with chemicals.

- Assess the risk of mechanical impacts, which can also influence the choice of the IP protection rating.

-

Assessment of the Type of Contaminants:

- Solids such as dust, sand, or metal filings that can penetrate the interior of the device.

- Liquids, including water, oils, or chemical solutions that could cause corrosion or short circuits.

-

Frequency of Exposure:

- Consider how often the actuator will be exposed to these contaminants. More frequent contact increases the need for higher protection.

- Also consider the duration of exposure, as prolonged influences require stricter protective measures.

-

Specific Requirements of the Application

- In industries like food processing or medical technology, often higher IP classes are required to meet strict hygiene standards.

- In electronics or precision instrument manufacturing, protection against the smallest particles is essential.

By carefully considering these factors, you can ensure that the selected electric actuator is optimally protected against environmental influences, thereby guaranteeing a long service life and reliable operation.

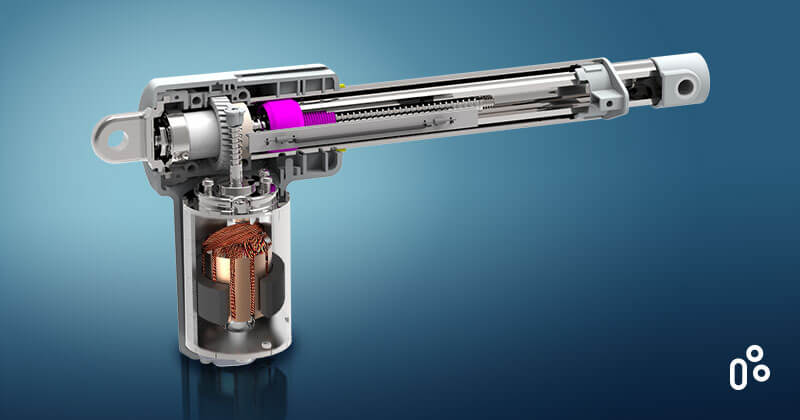

Lubrication and Maintenance

The type and amount of lubricant used in an electric linear actuator significantly affect its lifespan. Without lubrication, components wear out quickly and cannot work together. Lubrication helps to reduce friction between parts, which in turn helps to regulate the temperature in the motor to prevent overheating that could damage the device. It also reduces vibrations and noise and prevents corrosion of the device.

Primarily, greases and oils are used as lubricants. Grease is thicker than oil, allowing it to withstand higher stresses and reducing the frequency of maintenance needed for the device. TiMOTION uses specific types of grease depending on the load and speed requirements of the electric cylinder. Generally, a lubricating grease with higher viscosity (thinner) is used for applications with low load, and a lubricating grease with lower viscosity (thicker) is used for applications with higher load at operating temperatures from 5°C to 45°C.

Summary: The Importance of IP Protection Types

Choosing the correct IP protection type is crucial for the performance and longevity of electric linear actuators, especially in challenging environments. TiMOTION is committed to customizing each product specifically to the needs and conditions of our customers to maximize both safety and effectiveness.

We hope this chapter has provided you with a deeper understanding of the importance of IP protection types and their impact on the performance and safety of your electric actuators. Selecting the appropriate level of protection can significantly extend the life of your equipment and ensure it operates reliably under difficult conditions.

In our next chapter, we will delve into the key position feedback sensors used in electric linear motion systems. These sensors are vital for ensuring the precision and reliability of the systems and play a crucial role in the integration and performance of electric actuator systems.

TiMOTION is proud to be a leader in electric actuator technology, offering solutions tailored to the specific requirements of various industries. If you have any questions or need further information, do not hesitate to contact our experts. We are here to help you find the best solution for your needs and ensure that your equipment operates optimally.

Visit our website or contact our local team directly to learn more about our products and services and how we can assist you in achieving your goals.

Frequently Asked Questions (FAQ)

-

Why are IP protection types important?

IP protection types are crucial because they ensure that devices are protected from the intrusion of dust and water in various environments. By preventing contaminants from entering the devices, these protection types significantly enhance the lifespan and maintain operational quality. This minimizes the risks of failures and maintenance needs, ensuring consistent and reliable performance under various environmental conditions.

-

What does the IP rating mean for electric actuators?

The IP rating, short for "Ingress Protection," classifies and rates the level of protection an electrical device has against the intrusion of solid particles (like dust) and liquids. A higher IP number indicates better protection against environmental influences.

-

How do you choose the right IP protection type for electric actuators?

Choosing the right IP protection type mainly depends on the environment in which the actuator is used. In dusty or wet environments, higher protection types like IP66 or IP67 are necessary to ensure long-term performance and safety.